TANK CLEANING MACHINES

Our Bio range of rotary spray heads (RSH) and rotary jet heads (RJH) is designed for sanitary industries, strictly following EHEDG and 3A regulations and specifications. These devices ensure thorough cleaning while meeting the highest hygiene and safety standards required in industries such as food and pharmaceuticals.

Our SC range covers a wide array of applications in non-sanitary industries like oil, pulp & paper, and liquid transport sectors. This range offers robust cleaning solutions for dirty tanks, with ATEX (Zone 0 and 1) certified models available for hazardous environments in the oil and petrochemical industries. Whether maintaining cleanliness in sensitive environments or tackling challenging cleaning tasks in industrial settings, Scanjet provides tailored solutions to meet diverse industry needs.

What Makes the Bio RSH Different?

The Bio RSH series comprises three models of varying sizes, each offering different connection options (refer to the photo at the bottom of the page). These options simplify installation, whether you’re installing a new CIP tank cleaning system or upgrading an existing one with ordinary spray devices.

Furthermore, the Bio RSH is compatible with the Scanjet WASHTRAC sensor, allowing continuous monitoring and verification of its operation.

While other spray devices exist on the market, none compares to the Bio RSH. The Bio RSH cleans more effectively and produces superior outcomes compared with the simplest design, the static spray ball. Its unique design also uses less water and chemicals, providing better results while reducing costs and environmental strain.

Additionally, unlike rotating devices based on ball-bearing designs, the Bio RSH uses a fluid-bearing rotary mechanism. This design feature ensures a longer service life, typically 2-3 times that of conventional rotary spray balls. Consequently, you experience lower replacement costs, less maintenance downtime, and simpler operations.

Why Choose the Bio RSH?

Key Features

- Fluid-bearing.

- Self-cleaning.

- Self-draining.

- 360° impact coverage.

- Surface finish roughness: Ra = 0.8 μm (30 μ inch); others finishes available on request.

Standards

- Designed to EHEDG and GMP guidelines.

- Available with EN10204-2.1, 2.2 or 3.1 material and FDA 21CFR compliance certificates.

- Available with 3A-certification (clip-on and weld-on connections).

Ideally Suited For:

- Mixing vessels.

- Beverage storage tanks.

- Yeast tanks.

- IBC’s.

- Barrel cleaning.

Benefits

- Low water and detergent use.

- Much better cleaning outcome than with static spray balls.

- Much longer life than conventional ball-bearing designs.

Bio Series | Rotary Jet Heads

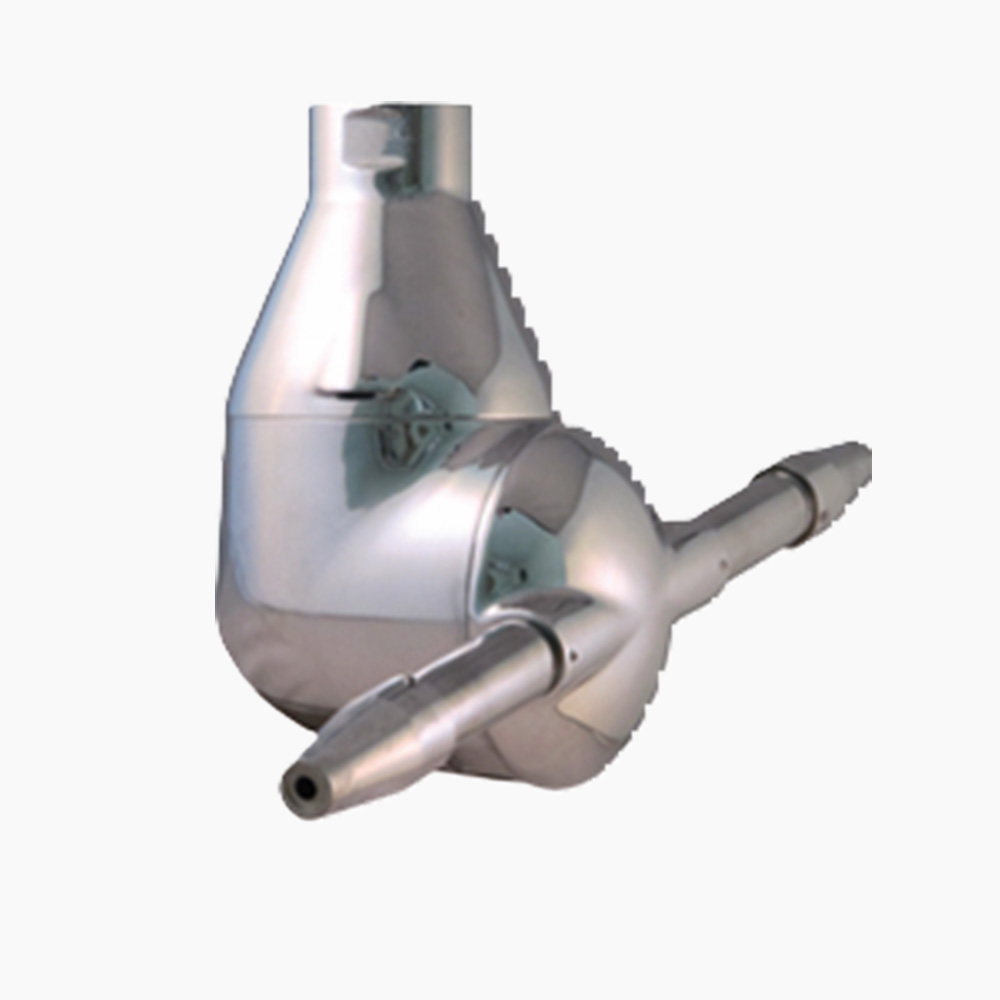

BIO 25

The hygienic tank cleaning machine, Scanjet Bio 25 rotary jet head, provides 360° coverage within a given tank or process vessel. It self-powers through the flow of fluid through the inlet cone. Increasing pressure and flow correspondingly lengthen the jet, impacting tank or vessel surfaces. Exclusive self-washing features.

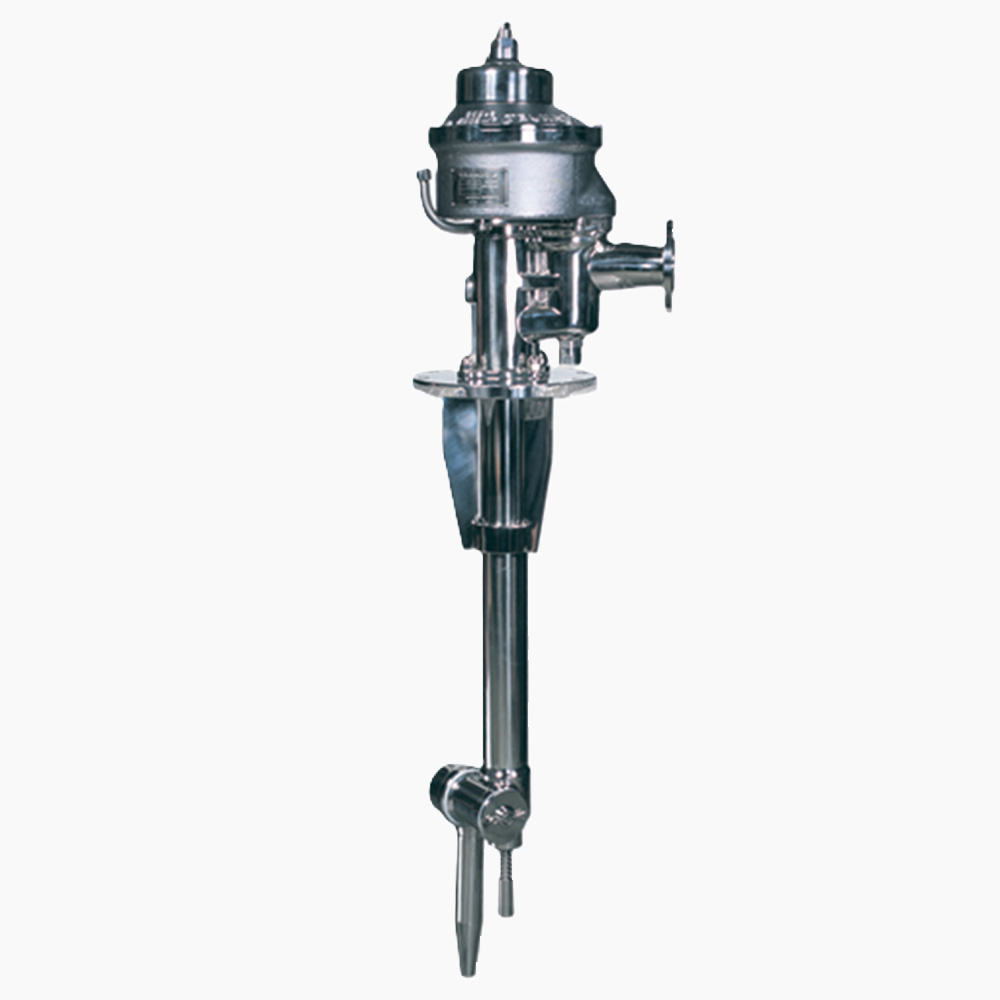

BIO 50

The highest-capacity model in the Bio range is the Scanjet Bio 50, designed to handle the largest vessels in the food and beverage industry. This highly polished tank cleaning machine self-powers via the flow of cleaning medium through the inlet cone. Increasing flow and pressure lengthens the jet, impacting the tank or vessel side.

Bio Series | Rotary Spray Heads

BIO 5SB

The Scanjet Bio 5SB efficiently replaces traditional static cleaning devices, offering 360° impact coverage, self-cleaning, and self-draining. Its patent-pending design follows EHEDG and GMP guidelines and can be supplied with EN10204-2.1, 2.2, or 3.1 material and FDA 21CFR compliance certificates.

SC Series | Rotary Jet Heads

SC 15TW

The SC 15TW is a 1.5” two- or four-nozzle automated tank cleaning machine made of 316 stainless steel and other highly corrosion-resistant materials. It maintains a fixed to moving gear ratio of 47 to 49, allowing it to produce a homogeneous 360° pattern that surpasses that of any other rotary jet head in its class.

SC Series | Single Axis Single Jet

SC 60A

The SC 60A is an advanced tank cleaning nozzle especially designed for crude oil storage tanks where tank entry is restricted or limited. The SC 60A can be inserted into the tank via the support leg holes of floating-roof tanks, as well as other similar openings as may be available on the tank.

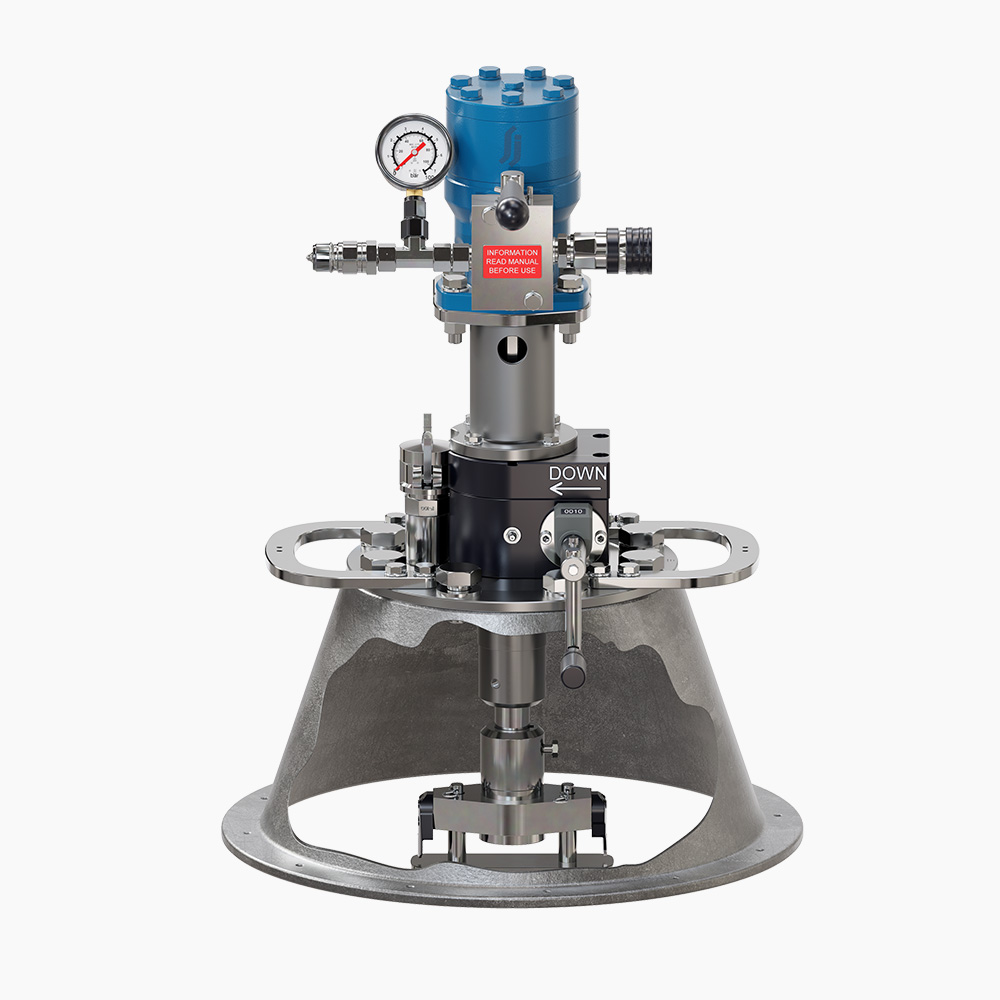

SC 60H

The SC 60H is an advanced hydraulic operated tank cleaning machine designed for crude oil storage tanks with limited access, providing a no-man entry solution. The slim design enables the SC 60H to fit through support leg openings on floating-roof tanks or similar access points.

SC 90A

The SC 90A is a single-nozzle tank cleaning machine especially developed for sector cleaning of tanks/cisterns/vessels in hazardous ATEX classified areas. It allows the user to focus the cleaning effort where needed, thus helping to optimize the cleaning process.

Certificates