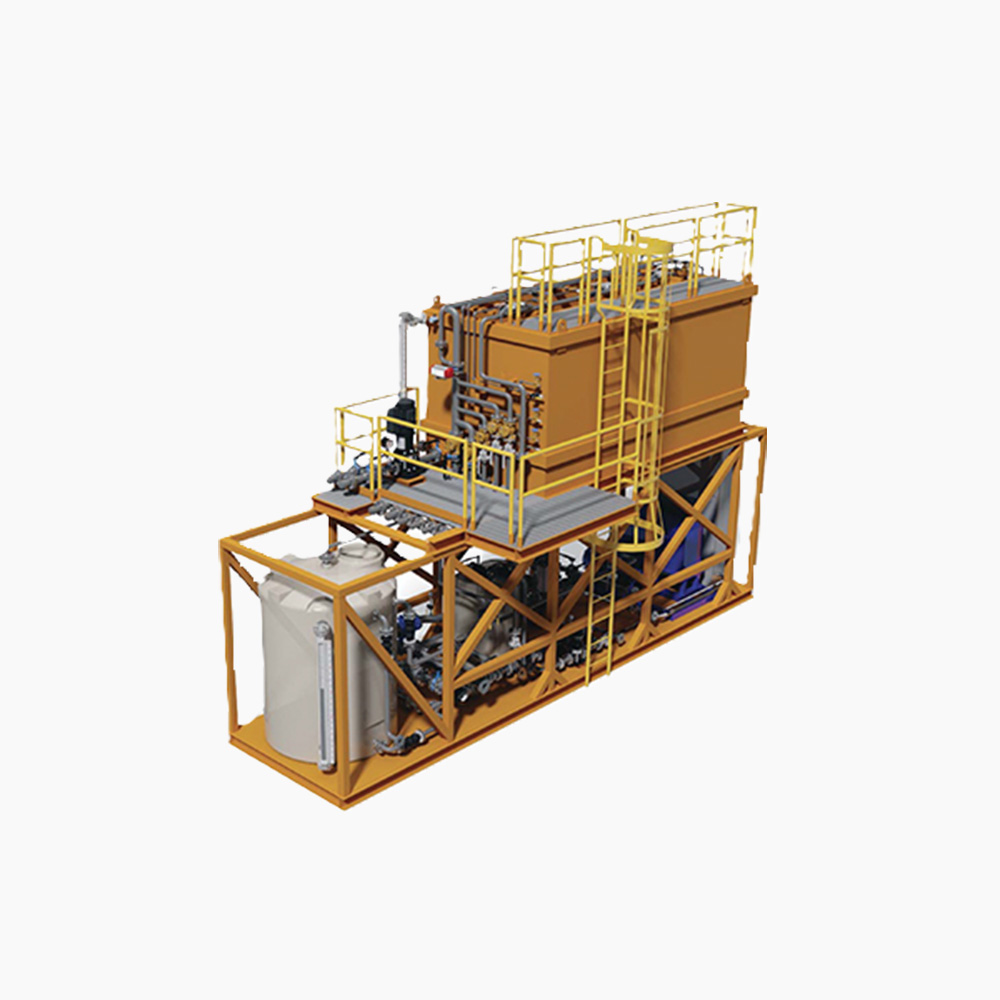

CIP System 3087 is a skid-mounted Clean In Place (CIP) System, adhering to ATEX standards for explosion-proof operation. Its multi-tank design enhances versatility and functionality, allowing for efficient and thorough cleaning. This reduces downtime and increases productivity. Additionally, the system ensures safety in hazardous environments with its explosion-proof certification according to ATEX standards. These features make it a reliable choice for Clean In Place operations in industrial settings.

INDUSTRIAL

CIP SYSTEMS

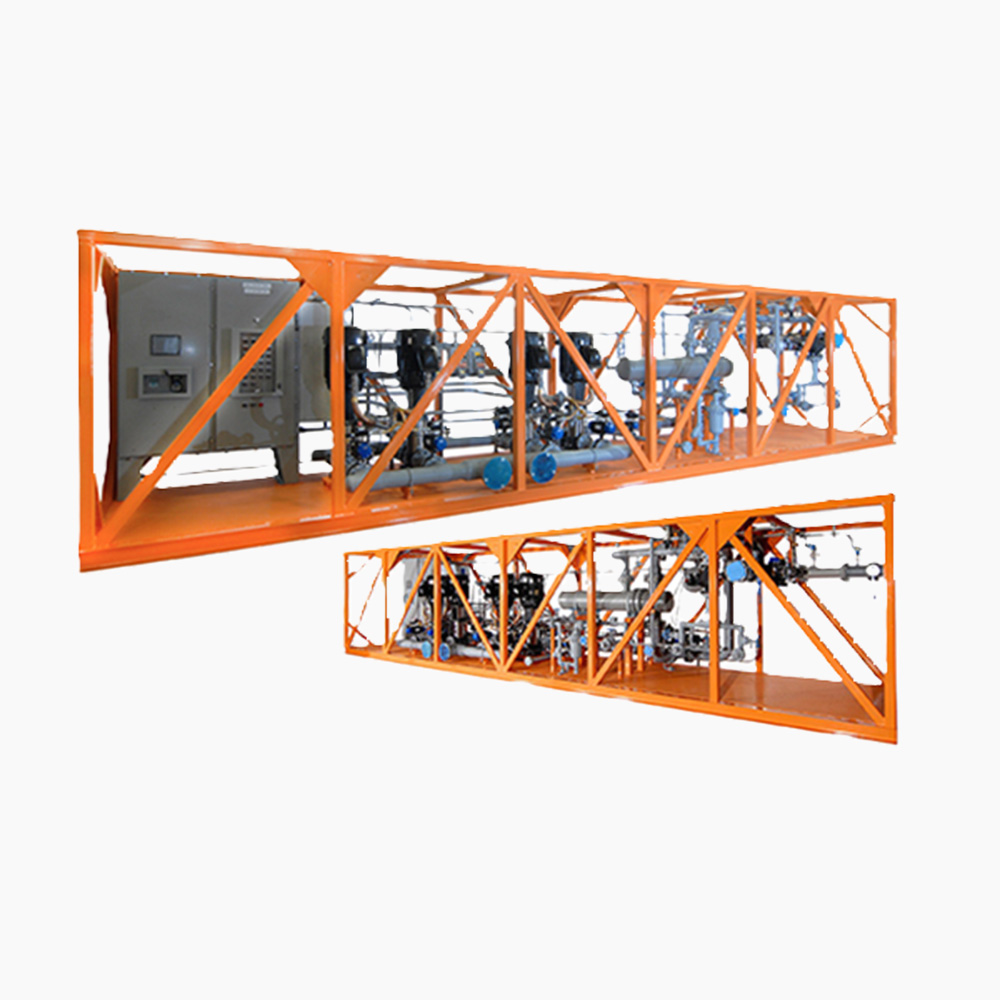

Scanjet provides fully automated tank cleaning systems for oil and petrochemical sectors, ensuring thorough cleaning and solid remediation. Our systems achieve less than 5% oil-on-solids, often less than 2%, as measured by a retort.

APPROVALS

Certificates

Accreditation, compliance and sponsoring.